Newgate Air Systems UK Ltd

Tyne and Wear ,

United Kingdom

(+44) 0191 262 3015

http://www.newgateair.co.uk

United Kingdom

(+44) 0191 262 3015

http://www.newgateair.co.uk

Newgate Air Systems UK Ltd - Wallsend

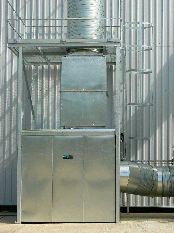

Dust & Fume Extraction - Our Organisation & Experience

The company which is at present known as Newgate Air Systems UK Ltd has been running in the dust and fume extraction and control industry for more than thirty years. We hold extensive project files for our dust and fume extraction installations going back over fifteen years. This has proven beneficial on many occasions when assessing the customers dust and fume extraction installation for compliance with present health & protection legislation.

Dust & Fume Extraction - Installation Teams

The NAS dust and fume extraction installation team is well stable. We have an powerful fusion of experience with more currently qualified engineers. Our installation team undergoes constant training, which covers appreciation of new dust and fume extraction goods and processes and secure working.

Dust / Fume Extraction System Installations - Safe Working

Confirming that our dust and fume installation team functions securely is of paramount importance to us and our clients. The team undergoes standard protection refreshers to ensure that all our members have Health & Safety Passports and Skill cards. The organization also offers CHAS registration. Safety inductions are performed on customer sites along with a Method Statement & Risk Assessment are produced for every dust or fume extraction installation project that we undertake.

Dust & Fume Extraction - Latest Measuring Equipment and For Lowest Cost

Recent years have examined the development of increasingly strict devices for producing readings relating to air quality. Critically significant decisions are made on the basis of information produced from such equipment. Systems specified and designed on the basis of inaccurate measurements will cause extraction of systems that are unnecessarily costly and which will not meet H&S laws. Given the impact of the accuracy of such measurements, Newgate Air Systems invests in the much appropriate measuring equipment, assuring that we design the maximum solutions for our customers dust and fume extraction needs.

We work in a range of commercial environments, including engine vehicle manufacture, welding vegetation, spray booths, furnaces, casting plant, woodworking vegetation, joiner’s workshops and laboratories.

| Business Operation Hours | ||

| Monday |

9:00 AM to 5:00 PM |

|

| Tuesday |

9:00 AM to

5:00 PM

| |

| Wednesday |

9:00 AM to 5:00 PM |

|

| Thursday |

9:00 AM to 5:00 PM |

|

| Friday |

9:00 AM to 5:00 PM |

|

| Saturday |

Closed |

|

| Sunday |

Closed |

|

Other HVAC Services : Heating Repair,

Service Type : Yes, this business serves customers at their Location

HVAC Services

HVAC Services

Cost effective dust and fume extraction and control systems.

Additional Information

Additional Information

Woodworking Waste Extraction & Collection

Collection of dust and waste material from wood working machinery in small scale joiners shops, large scale production facilities and sawmills.The extraction system options range from central extraction systems to bespoke collection / filtration units and cyclones. Individual machine extraction and collection is frequently required.

Production Facility Dust Extraction

Any production facility generating dust from materials and / or process requires a system for the removal of the dust from the working area and the collection of this dust for disposal. Examples of dust generating activities include pharmaceuticals, chemicals, cement, ink powders and shot blasting.

Forge Extraction

Extraction for forging activity will also need to remove waste material and lubrication residues by special combined filtration and collection equipment.

Machining Facility - Air Filtration & Recirculation

Machining facility extraction includes removal of waste material and lubrication residue, namely oil mist, either by an individual centrifugal type collector or larger scale ducted central filtration units. The filters are designed to remove the fines and the machine oil, before the air is exhausted back into the work space or to atmosphere.

Languages Spoken

Languages Spoken

English

Payment Options

Payment Options

Visa

Visa Master Card

Master Card Cash

Cash Check

Check Bill

Bill

Year Established

Year Established

Write a review for Newgate Air Systems UK Ltd

* Review Title

* Review